Pump FAQ’s (Frequently Asked Questions)

Please find below a collection of frequently asked questions in relation to pumps. If there is a question that you cannot see below please contact us directly and a member of our team will be in touch to assist you further.

FAQ for Pumps

General Information

Q: What is a pump?

A: A pump is a mechanical device used to move fluids (liquids or gases) or slurries by mechanical action. Pumps operate by some mechanism (typically reciprocating or rotary), and consume energy to perform mechanical work by moving the fluid.

Q: What are the main types of pumps?

A: The main types of pumps include:

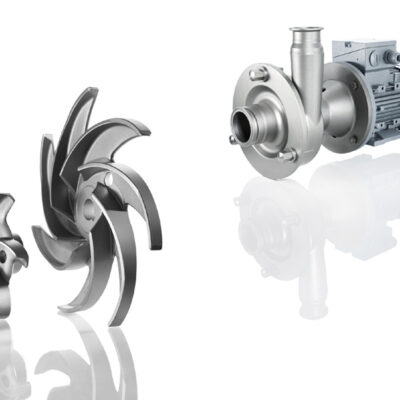

Centrifugal Pumps: Use rotational kinetic energy to move fluids.

Positive Displacement Pumps: Move fluid by trapping a fixed amount and forcing (displacing) that trapped volume into the discharge pipe.

Peristaltic Pumps: Use a rotor to compress and move the fluid through a flexible tube.

Diaphragm Pumps: Use a diaphragm and check valves to move fluids.

Selection and Usage

Q: How do I choose the right pump for my application?

A: When selecting a pump, consider factors such as:

The type of fluid being pumped (viscosity, temperature, corrosiveness).

The flow rate and pressure requirements.

The distance and height the fluid needs to be moved.

The power source availability and efficiency requirements.

Maintenance and operating costs.

Q: What is the importance of the pump curve?

A: The pump curve (or performance curve) shows the relationship between the flow rate and the head (pressure) for a specific pump. It helps in selecting the right pump for your application and ensures that the pump will operate efficiently under the desired conditions.

Maintenance and Troubleshooting

Q: How often should a pump be maintained?

A: The maintenance frequency depends on the type of pump and its operating conditions. Generally, regular checks should be done monthly, with more thorough inspections and maintenance every 6 to 12 months. Always refer to the manufacturer’s recommendations for specific maintenance schedules.

Q: What are common signs of pump problems?

A: Common signs include:

Reduced flow rate or pressure.

Unusual noises (grinding, whining, or banging).

Leaks around the pump.

Increased vibration.

Overheating of the pump motor.

Q: What should I do if my pump is not working properly?

A: If your pump is not working properly:

Check the power supply and connections.

Ensure there are no blockages in the intake or discharge lines.

Verify the pump is primed if it’s a centrifugal pump.

Check for leaks or worn-out seals.

Consult the pump’s manual for specific troubleshooting steps or contact a professional.

Installation and Operation

Q: How should a pump be installed?

A: Follow these general steps for pump installation:

Ensure a solid and level foundation to minimize vibrations.

Use proper alignment tools for coupling the pump to the motor.

Install appropriate suction and discharge piping with minimal bends and restrictions.

Use flexible connectors to accommodate thermal expansion and vibrations.

Follow the manufacturer’s installation guidelines for specific requirements.

Q: What is pump cavitation and how can it be prevented?

A: Cavitation occurs when vapor bubbles form in the liquid being pumped and collapse, causing damage to the pump components. To prevent cavitation:

Ensure adequate NPSH (Net Positive Suction Head) available.

Avoid excessive pump speed.

Maintain proper suction conditions and avoid high temperatures.

Use larger diameter suction pipes and minimize the length and number of fittings.

Q: Are there any regulatory standards for pumps?

A: Yes, pumps are often subject to various regulatory standards, including:

ANSI (American National Standards Institute)

ISO (International Organization for Standardization)

API (American Petroleum Institute)

CE (Conformité Européenne) marking for products sold in the European Economic Area. Compliance with these standards ensures safety, reliability, and performance.

Energy Efficiency

Q: How can I improve the energy efficiency of my pump system?

A: Improve energy efficiency by:

Selecting the right size pump for your application to avoid overworking or underworking the pump.

Using variable frequency drives (VFDs) to adjust pump speed according to demand.

Regularly maintaining the pump and system to ensure optimal operation.

Reducing friction losses in the piping system.

Using high-efficiency motors and components.

Additional Resources

Q: Where can I find more information on pumps?

A: For more information, you can view our pump literature for all the manufacturers we supply

.